In the kitchenware business, one of the most common questions we receive from buyers is:

“Can your silicone oven gloves really handle 500°F?”

At first glance, this sounds like a simple technical question. But for people who work in manufacturing or trading—like me—it often turns into a small adventure that involves testing labs, suppliers, and sometimes even a baking shop!

Where Does the 500°F Come From?

When you see “500°F” on a product page, it usually refers to the temperature rating of silicone material itself, not the result of a laboratory test.

In general, food-grade silicone can continuously withstand 230–250°C (446–482°F) and can tolerate short-term exposure up to around 280°C (536°F).

This is why many factories or sellers label their oven gloves as “heat resistant up to 500°F.” It’s an industry standard reference, not a fixed number tested for every model.

However, when a buyer really wants to confirm it, that’s when things get more serious—because real testing means actual ovens, thermometers, and timing.

How a Real 500°F Test Is Done

Recently, a UK customer asked us to prove the glove’s performance at 500°F.

I checked with my supplier, and they shared a story from another client:

That client’s quality inspector went to a local bakery, borrowed their commercial oven, set it to 500°F (about 260°C), and placed the glove inside for testing.

After heating for 10–15 seconds, they used the glove to remove a baking tray. The surface showed no deformation, no sticky smell, and no visible damage—so it was approved.

This kind of “real kitchen test” is actually quite common.

It’s not as formal as a lab report, but it reflects the glove’s practical usability—which is what end-users really care about.

Why Do We Still Need a Lab Test?

Some professional buyers, especially in the UK or EU, prefer to have an official test report to include in their product files or Amazon listings.

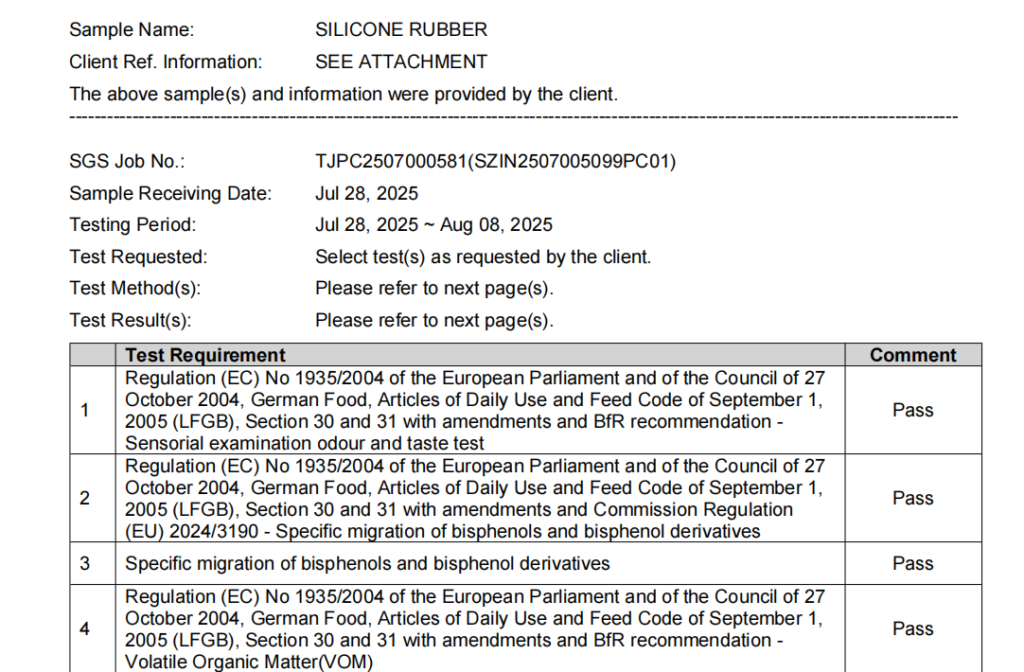

In that case, we can arrange a test through labs like SGS or Intertek.

Such a test uses a controlled oven environment—usually 260°C (500°F) for 30–60 seconds—and then checks whether the glove remains intact and odor-free.

The testing process takes about 10–12 working days.

Before doing it, both buyer and supplier should confirm:

- The exact temperature and time for testing,

- What counts as a “pass” (no color change? no melting?),

- And who covers the cost.

About the Cost

In most cases, a sample preparation and testing fee around USD 150 is required.

This covers producing a new LFGB-grade sample and sending it to the lab.

We usually offer a fair deal: the sample fee is refundable once the bulk order is placed, and our factory can share part of the testing cost.

It’s not a small amount, but it gives both sides peace of mind.

After all, once the glove passes the test, it’s a strong selling point for everyone involved.

What Buyers Should Know Before Testing

Testing at 500°F sounds exciting, but not every silicone glove truly reaches that level.

Different silicone formulations and wall thicknesses affect performance.

Some cheaper compounds can only handle 230°C safely.

So before jumping into testing, it’s always wise to:

- Confirm the raw material data with your supplier;

- Agree on test conditions (temperature, duration, and criteria);

- Prepare samples that match production quality—otherwise, results may differ.

A test is only meaningful when it reflects the real product.

Final Thoughts

Heat resistance is one of the most talked-about yet misunderstood topics in silicone kitchenware.

The “500°F” label is not magic—it’s simply based on material capability and short-term endurance.

As a salesperson working in a silicone and plastic kitchenware factory, I’ve learned that clear communication matters more than numbers.

When both sides—buyer and factory—understand how the test works and what it proves, cooperation becomes smoother, and trust naturally grows.

So next time someone asks, “Can your oven glove really handle 500°F?”

I’ll smile and say:

“Yes—but let’s also talk about how we test it.”