When people talk about sourcing kitchen utensils from China, they often think of product quality, pricing, and manufacturing capabilities. But there’s something equally important that’s often overlooked—packaging.

For clients who want to sell kitchen utensil sets—especially those launching new products—packaging isn’t just a box. It’s a part of the product experience. It needs to be functional, cost-effective, and visually appealing. Most importantly, it must fit the product perfectly. If the box is too tight, packing becomes difficult. If it’s too loose, the tools might move around during shipping. That’s why our job doesn’t end after making the utensils. We go one step further to help customers with box sizing and packaging design.

Let me share a recent case to show how we work closely with clients from start to finish—even when it comes to something as detailed as the box size.

A New Client, A New Product

Recently, I had a new client who was preparing to launch a liner set of five kitchen utensils. This was their first time working with our factory, and they were full of energy and ideas. The set included five different tools—each with its own shape and length—so it wasn’t a simple job to figure out what size box would fit the full set neatly and securely.

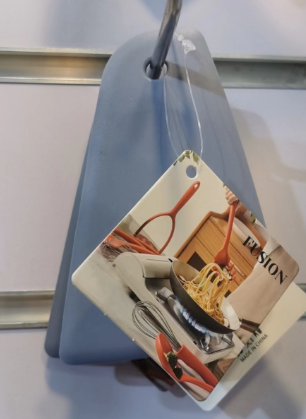

He already had a vision for the product and wanted to make sure the packaging would not only look nice but also be precise in size—just enough to pack the full set in a brown kraft box, which is common for eco-conscious brands.

But here’s the challenge: when you don’t know the final box size, how can you design your color sleeve or label? And how do you know if your packaging costs will stay within budget?

That’s where we came in.

Step 1: Collecting the Details

The first step was to ask the client for the final version of the tools—especially any handle curves, head thickness, and how he planned to pack them (side by side or stacked).

Once we confirmed all the dimensions and confirmed that there would be no color inserts or separators inside the box, we moved to the next stage—box sampling and packing test.

Step 2: Coordinating with the Box Factory

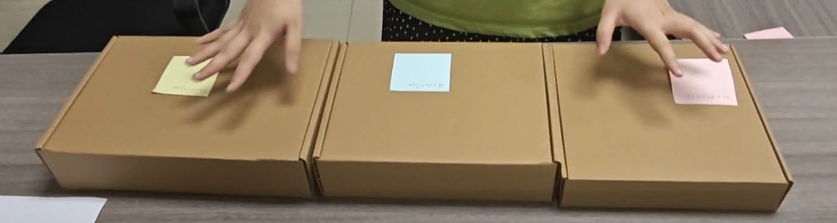

I immediately contacted our trusted printing partner and explained the situation. Since the client was unsure about the exact size, we proposed creating three sample boxes—each with slightly different dimensions. This way, we could actually try packing the utensils and see which size worked best in real life, not just on paper.

This is something many trading companies or inexperienced suppliers won’t do. But because we’re a direct factory and have long-term relationships with box suppliers, we can move quickly and make things happen.

Step 3: Making and Testing the Boxes

After a few days, the box factory delivered the three brown box samples. I took a video of myself packing the full set of five tools into each box, showing how they fit, how tight or loose the space was, and how easy it was to close the box. I didn’t just send photos—I sent a clear, detailed video with my explanation.

In the video, I pointed out:

- Which box made the tools feel too squeezed

- Which one had extra space and might need more filler

- Which one I personally recommended and why

Clients really appreciate this kind of detail. It helps them visualize the packing process and make decisions with confidence—even if they’re thousands of miles away.

Step 4: Giving Professional Advice

After the video, I also sent a message with my recommendation on the most suitable box size. I explained that one box offered just the right amount of space for the tools to sit comfortably and safely without rattling during shipping.

My goal wasn’t just to “do what the client says,” but to think ahead—just like a teammate would. I reminded the client to consider not only the box size but also the final weight, shipping cost, and whether to leave space for any printed insert or flyer inside.

This kind of advice helps build trust. Clients know we’re not just here to take orders—we’re here to support their brand’s success.

Why This Matters for Customers

Whether you’re launching a single tool or a full kitchen utensil set, packaging should never be an afterthought. The wrong box size can cause:

- Higher shipping costs

- Poor customer unboxing experience

- Damage during transit

- Waste of material and money

That’s why we offer box testing and advice as part of our value-added service. Even though we’re a kitchen utensil factory, we understand the full supply chain, from mold-making to manufacturing to packaging.

We want to make life easier for our clients—especially those who are still growing their brand or trying something new in the market.

We’re Problem Solvers, Not Just Product Makers

This case is just one example of how we treat every order as a project, not just a transaction. We don’t wait for the client to find problems—we try to predict them in advance and offer solutions.

Some people think that working with a Chinese factory means language barriers or lack of flexibility. But I hope this story shows that when you choose the right factory partner, communication can be smooth and efficient. And yes—we can speak your business language, not just English.

What We Can Offer You

If you’re developing a new kitchen utensil set—whether it’s 2pcs, 5pcs, or 10pcs—we can help you with:

- Product design advice

- Packaging solutions and box sizing

- Customized logo printing

- Drop test support

- Short video packing tests

- Fast sampling and feedback loops

Even if you’re still in the idea stage, feel free to reach out. We’re happy to offer suggestions based on our 29 years of experience in silicone and plastic kitchenware manufacturing.

We’ve worked with big brands like Zwilling and Nitori, but we also enjoy helping small businesses grow.

In today’s competitive market, details matter. A great product needs the right packaging. And a great factory partner needs to go beyond making the product—they must help you succeed in the real world.

If you’re looking for a kitchenware supplier who can not only produce high-quality tools but also support you with practical packaging advice, testing, and fast responses, we’re here for you.

Let us be part of your product journey—from design to delivery.