Behind every well-crafted kitchen utensil lies a sophisticated molding process. Molding is a critical step in manufacturing utensils, determining their durability, functionality, and aesthetic appeal. In this post, we delve into the science of molding kitchen utensils, exploring various techniques and technologies that shape these essential tools.

Molding is the process of shaping raw materials into finished products using molds. There are several molding techniques commonly used in the production of kitchen utensils:

- Injection Molding: This is one of the most widely used techniques for manufacturing plastic and silicone utensils. It involves injecting molten material into a mold cavity under high pressure. Once cooled and solidified, the mold opens, and the finished product is ejected. Injection molding allows for complex shapes, precise detailing, and high production volumes, making it suitable for mass production.

- Compression Molding: Used primarily for manufacturing silicone utensils, compression molding involves placing pre-measured silicone material into a heated mold cavity. The mold is then closed, and pressure is applied to compress the material into the desired shape. After curing and cooling, the mold opens, and the finished utensil is removed. Compression molding is favored for its ability to produce durable, heat-resistant utensils with consistent quality.

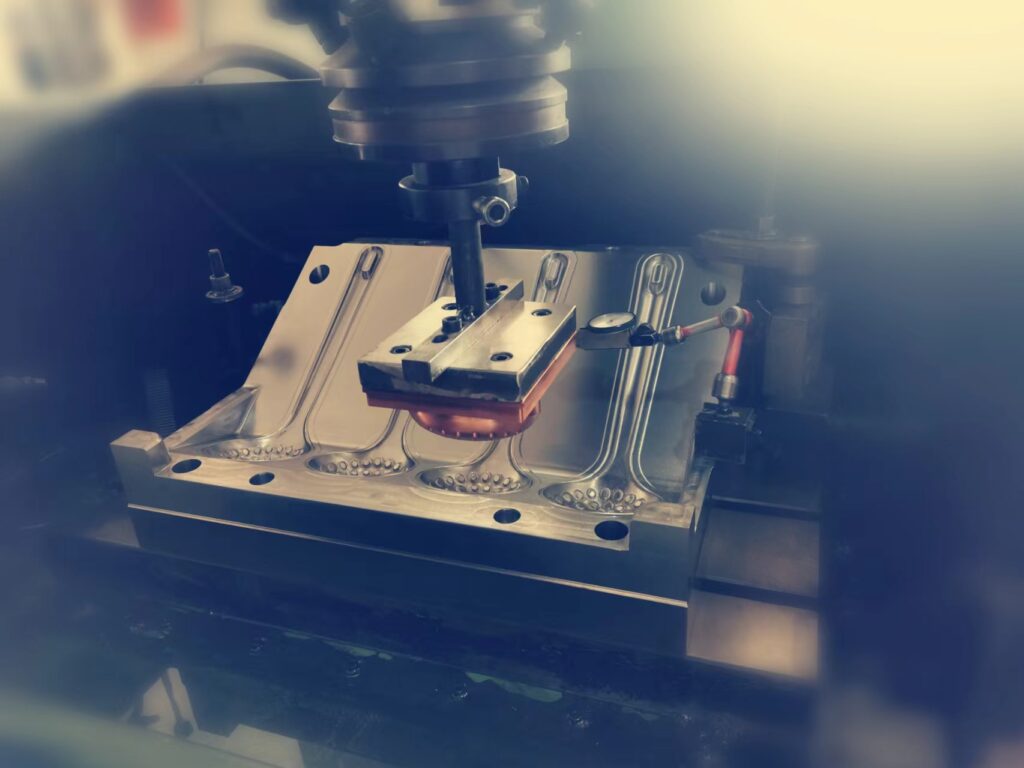

- Die Casting (for Metal Utensils): Die casting is used for producing metal utensils, such as stainless steel kitchen tools. It involves injecting molten metal into a steel mold cavity under high pressure. Once cooled and solidified, the mold opens, and the metal utensil is extracted. Die casting ensures precise shapes and high tensile strength, making it ideal for heavy-duty utensils.

Injection Molding: Precision and Efficiency

Injection molding is particularly favored for its precision and efficiency in producing plastic and silicone kitchen utensils. The process begins with the selection of raw materials, typically granular or powdered forms of plastic or silicone polymers. These materials are melted and injected into a mold cavity, where they take the shape of the mold under high pressure.

Key advantages of injection molding include:

- Complex Shapes: Injection molding allows for intricate designs and complex geometries that would be difficult or impossible to achieve with other manufacturing methods.

- Consistency: The process ensures uniformity and consistency in each batch of utensils, minimizing variations and defects.

- High Production Rates: Injection molding is capable of producing large quantities of utensils in a relatively short amount of time, making it cost-effective for mass production.

Compression molding is preferred for manufacturing silicone kitchen utensils due to its ability to produce durable, heat-resistant products. The process begins with measuring and mixing silicone compounds, which are then placed into a heated mold cavity. The mold is closed, and pressure is applied to compress the material into shape. Heat and time are then used to cure the silicone, solidifying it into the final utensil.

Key advantages of compression molding include:

- Heat Resistance: Silicone utensils produced through compression molding can withstand high temperatures without deforming or melting, making them ideal for cooking and baking.

- Durability: The compression molding process results in dense, durable utensils that resist wear and tear over time.

- Versatility: Compression molding allows for the production of a wide range of silicone utensils, from spatulas and baking mats to oven mitts and ice cube trays.

Advancements in molding technologies continue to drive innovation in the kitchen utensil industry. Emerging technologies such as 3D printing and rapid prototyping are revolutionizing how utensils are designed and manufactured. 3D printing, for example, allows designers to create prototypes and customized utensils quickly and with minimal material waste.

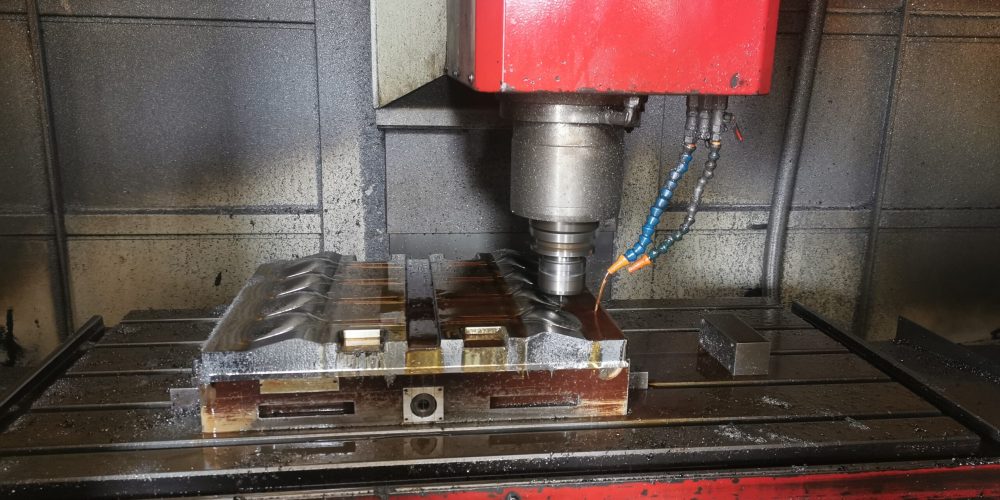

Furthermore, smart manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable precise control over every aspect of utensil production. These technologies enhance efficiency, reduce production costs, and support the development of cutting-edge designs.

The molding process is the backbone of quality kitchen utensils, defining their durability, functionality, and aesthetic appeal. Whether through injection molding for plastic and silicone utensils or compression molding for heat-resistant silicone products, manufacturers rely on advanced techniques to produce utensils that meet the highest standards of performance and reliability. As technology continues to evolve, so too will the methods and materials used in molding, ensuring that kitchen utensils remain essential tools for culinary enthusiasts around the world.