There’s many kinds of package for different item, following design just for reference:

Tie Card

Sleeve Card

Tag Card

Color Box

Display Box

Here’s also list a series of way for printing logo as following:

Silk Printing

Laser Printing

Embossed Printing

For customized a new design, it’s our working flow as following:

1. Initial Consultation and Concept Design

a. Client Meeting:

- Discuss the client’s vision, requirements, and any specific features they want.

- Review any initial sketches or ideas the client may have.

b. Market Research:

- Analyze current market trends and competitor products.

- Identify potential gaps in the market that the new spatula design could fill.

c. Concept Sketches:

- Create preliminary sketches based on the client’s input and market research.

- Get feedback from the client and refine the sketches as necessary.

2. Detailed Design and Prototyping

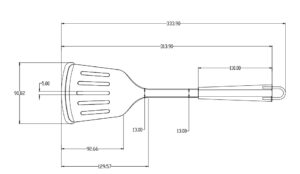

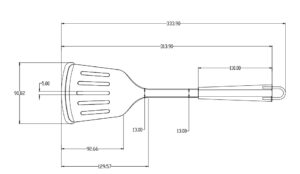

a. CAD Modeling:

- Develop detailed 3D models using Computer-Aided Design (CAD) software.

- Ensure the design meets ergonomic, aesthetic, and functional requirements.

b. Material Selection:

- Choose suitable materials (silicone, plastic, or a combination) considering factors like heat resistance, flexibility, durability, and safety.

c. Prototype Creation:

- Use 3D printing or other rapid prototyping methods to create a physical model of the slotted turner.

- Allow the client to review and test the prototype.

3. Tooling and Mold Design

a. Mold Design:

- Design molds for the slotted turner based on the final CAD model.

- Ensure the mold design allows for efficient manufacturing and minimal waste.

b. Mold Fabrication:

- Create the molds using CNC machining or other appropriate techniques.

- Test the molds for accuracy and functionality.

4. Manufacturing

a. Material Preparation:

- Source high-quality silicone, plastic and stainless steel materials.

- Prepare the materials by heating, mixing, stamping, polishing processes.

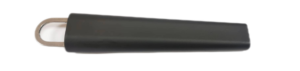

b. Stamping Molding

- Get the specific metal part from stamping process

- Then polishing the edge

c. Injection Molding:

- Use injection molding machines to produce slotted turner’s handle

- Monitor the process to ensure consistency and quality.

d. Vulcanization Molding

- First vulcanization help the slotted turner get the silicone part with toughness

- Second vulcanization help to get purified effect and evaporate harmful substances.

5. Quality Control

a. Inspection:

- Inspect slotted turner for defects or inconsistencies.

- Test for durability, flexibility, heat resistance, and other relevant factors.

b. Client Review:

- Provide samples to the client for final approval.

- Make any necessary adjustments based on client feedback.

6. Packaging and Shipping

a. Packaging Design:

- Design functional and attractive packaging.

- Ensure packaging protects the product during shipping and is eco-friendly if possible.

b. Production:

- Pack the item in the designed packaging.

- Prepare the packaged products for shipping.

c. Logistics:

- Coordinate with shipping companies to ensure timely delivery.

- Provide the client with tracking information and delivery updates.

7. Post-Launch Support

a. Customer Feedback:

- Gather feedback from the client and end-users.

- Use feedback to make any future improvements.

b. Continuous Improvement:

- Monitor the product’s performance in the market.

- Stay updated with industry trends and innovations to keep the product competitive.